Frozen Sushi: Flash Freezing Japanese Sushi

Frozen Sushi: Why Analyze It?

In order to realize the most efficient methods of freezing foods, we must first understand what it is that constitutes the product that is intended to be frozen. Understanding the constituents of the food makes it easier to quantify the resources necessary to make the most efficient freezing techniques for a wide variety of foods and products. For this purpose, we conduct comprehensive food analysis prior to any further endeavor. This allows for the most efficient use of resources as well as helps us devise methods to ensure that you receive the best in freezing technology catered specifically for your product.

Preface

Food Analysis – Food analysis is a discipline that deals with the application and understanding of the complex analytical procedures for characterizing the properties of foods and their re-activities to different conditions. These procedures are used to provide information about a wide variety of different characteristics of foods, inclusive of their composition, structure and physicochemical properties. This information is critical to our rational understanding of the factors that determine the properties of foods, as well as to our ability to freeze foods and products that are consistently safe, nutritious and desirable for consumers. Over the course of this analysis, we will take a look at the technology we have used to ensure the best freezing results designed specifically for your inventory.

Prior To Freezing: Sushi

Prior to freezing the sushi, we made it our priority to ensure that we tested the best quality sushi we had at our disposal. This was to make sure that the results derived from the freezing sushi test were as consistent as possible with analytical data observed beforehand.

Prior to freezing, the texture, consistency, taste and weight of the sushi were noted and taken into consideration so as to allow comparison upon freezing and defrosting the sushi.

Please note the texture, quality and sheen of the sushi prior to freezing as it will be necessary to compare the two when the frozen sushi has been defrosted.

Starting the Freezing Process

Once all the relevant data has been collected, we can now move onto the process of flash freezing sushi.

For today’s test, we will be making use of our specialized Artlock Freezers.

The sushi can be arranged onto a tray which is then placed inside the Artlock Freezer. Our Artlock Freezers have slots for multiple trays so that you can easily freeze several batches at a time. This helps greatly boost productivity and output in the long run.

Once the sushi is placed within the freezer and the chamber is closed, the sushi freezing process can now begin.

Whether one or multiple trays are placed within the freezer, the 360° Coverage of the Artlock Freezer will ensure high quality freezing for the product regardless of placement or amount.

The sushi can be frozen in a very short amount of time. While we expected it to take a minimum of 45 minutes to freeze the sushi, we were pleased to find that the sushi was well frozen within a mere 30 minutes.

The Freezing Process: Cell Wall Preservation and Drip Loss:

We can take this opportunity to explain to you the process by which our flash freezers use the most advanced Japanese technology to ensure the highest quality frozen products.

In addition to all these features, our Freezers also ensure that the food passes the freezing threshold as fast as possible.

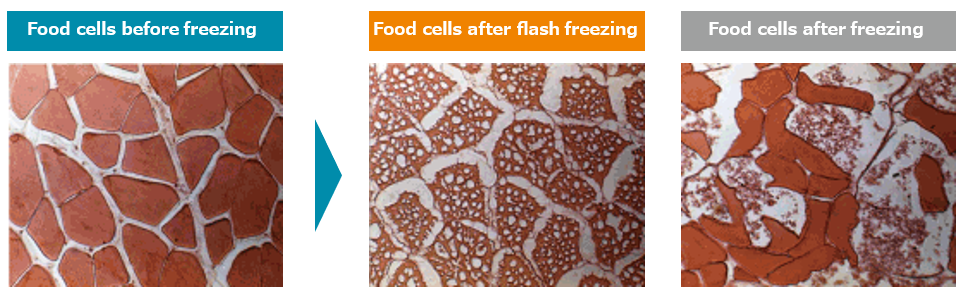

There is a common misconception when it comes to the concept of freezing. It is often thought that the lower the temperature, the better the quality of the frozen product. In actuality however, there is a certain freezing threshold that affects the quality of frozen goods more than any other factor. This threshold is the ice crystal forming threshold. It is during this stage that the cells within the product undergo crystallization. The longer food reminds within this threshold, the more likely it is for the cells within the food to be damaged.

Our freezers ensure that food passes this crucial stage and bypasses the threshold as fast as possible to as to minimize cellular degradation as much as possible. Doing so, leads to preservation of cellular integrity while achieving minimal loss in texture, quality and taste as well as helps reduce drip loss and maintain product weight.

Quick Overview on Drip Loss:

Drip Loss is the process by which food loses its texture and internal moisture upon defrosting. Often, when regular or inefficient freezers are used to freeze food, there is substantial internal damage to the cellular structure of the product. This causes the food to lose its weight and texture in the form of drip loss. This is a major issue for a lot of businesses because this leads to massive loss of inventory and reduction in product quality.

Now that we are in the clear about the issues surrounding freezing, and have a good idea as to what drip loss and freezing thresholds are, we can now move onto the results of Flash Freezing.

Flash Freezing Sushi : After Freezing

As seen in the pictures above, the sushi has been frozen completely from all directions via the 360° cooling of the Artlock Freezer.

The frozen sushi has maintained the same shape and size as it was prior to being frozen and the ice crystallization can be easily seen on the surface of the sushi. Please note the size of the ice crystals on the surface of the frozen sushi. Smaller ice crystals are a good indicator of high quality freezing. Larger ice crystals are indicative of irregular and inefficient freezing. In addition to this, larger ice crystals also cause more damage to the cells and the internal structure of the food, leading to reduction in quality and texture.

Given that the process of freezing is complete, we now wait up to an hour for the product to defrost at room temperature. Based on the average temperature of the location where the sushi is being frozen, the defrost time may vary.

After an hour of flash freezing, the flash frozen sushi had defrosted completely and was ready to be tested to see if the sushi had maintained its quality even after the intensive freezing and defrosting stages.

Flash Frozen Sushi : After Defrosting

Now that we have finished with the process of defrosting, we can check the sushi for changes in quality, taste, texture, weight as well as drip loss.

Now that the product has been defrosted, we can observe any changes in the quality of the sushi.

In terms of the look of the sushi, it mostly remains unchanged. If anything, the process of defrosting adds a natural rich sheen to the surface of the sushi. This is something that was not present prior to flash freezing sushi.

In addition to this, you may also notice that the shape of the sushi has remained unchanged. The individual grains of rice hold on firmly to one another as if they have been made by hand, fresh out of the kitchen.

Moreover, there is absolutely no drip loss noted which is a major factor in determining how well a product or in this case, sushi, has been frozen. This is an indicator of minimal cell wall destruction and high quality freezing. When it comes to freezing sushi and flash frozen sushi, this is an especially important factor as the texture of sushi is very delicate.

Moving onto the taste, we had both our Japanese as well as Foreign Staff taste the sushi and the decision was very unanimous. The quality of the sushi had not changed at all due to the process of freezing. In fact, quite a few people exclaimed that the defrosted sushi tasted better and had improved texture compared to the fresh sushi that had been placed inside a regular chiller for the past hour without any prior freezing.

In addition to this, we may also mention that most health advisory boards recommend freezing sushi prior to serving it as it greatly reduces the risk of ingesting harmful bacteria or parasites that are often present in raw fish like sushi and meat.

Preparing Your Own Sushi :

You may want to see our wonderful sushi machine lineup on our website if you want to start your own sushi company. You can not go wrong with our premium sushi machine listings with the emphasis placed on offering the truest Japanese sushi experience, while remaining cost effective, and incredibly rapid and efficient. Products from known sushi chefs from across the nation in the center of Japan are a few clicks away to start your own sushi.

Freezing Sushi Conclusion: Tests Speak For Themselves

Drawing from the results of the Flash Freeze Test, we may conclude that while flash freezing, the Artlock Freezer not only froze the sushi in a very short period of time, but also ensured minimal cell wall destruction and almost no drip loss whatsoever.

In addition to this, the sushi also maintained its flavor, texture, color and weight with no change in shape or characteristic making the Artlock Freezer an ideal choice for extremely high quality Artlock Flash Freezing.

If you are interested in freezing your sushi with the best freezing technology Japan has to offer, please do feel free to purchase our Artlock Freezers to give your business and investment the boost it needs to push itself to the top of the market with the highest quality Japan has to offer. You can reach out to us via the Blue Mail Toggle or by visiting our contact page.